Effective Ways to Prevent Weld Undercut in Your Welding Jobs

Effective Ways to Prevent Weld Undercut in Your Welding Jobs

Blog Article

Grasping the Art of Welding: Just How to Avoid Undercut Welding Issues for Flawless Construction Outcomes

By comprehending the root triggers of undercut welding and carrying out reliable strategies to stop it, welders can boost their craft to brand-new degrees of quality. In the search of remarkable fabrication results, mastering the art of welding to avoid undercut issues is not just an ability yet a need for those making every effort for excellence in their job.

Recognizing Undercut Welding

To prevent undercut welding, welders ought to guarantee appropriate welding specifications, such as changing the present, voltage, travel speed, and preserving the appropriate electrode angle. By comprehending the causes of undercut welding and executing precautionary steps, welders can accomplish premium, structurally sound welds.

Sources Of Undercut in Welding

Understanding the factors that add to damage in welding is crucial for welders to generate top notch, structurally audio welds. When the weld metal does not properly load the groove developed between the base metal and the formerly deposited weld metal, damaging happens. A number of factors can lead to damage in welding. One typical cause is too much warm input. Welding at high temperatures for extensive durations can result in the base steel thawing more than wanted, resulting in undercut. Poor welding wrong or current welding rate can likewise add to damage. Insufficient current might not offer enough warm to melt the base and filler steels sufficiently, while excessive rate can prevent correct fusion, creating undercut. Furthermore, inappropriate electrode angles or wrong lantern manipulation strategies can create locations of low weld metal deposition, advertising undercut. Comprehending these reasons and executing correct welding techniques can assist prevent undercutting concerns, guaranteeing long lasting and strong welds.

Techniques to stop Undercutting

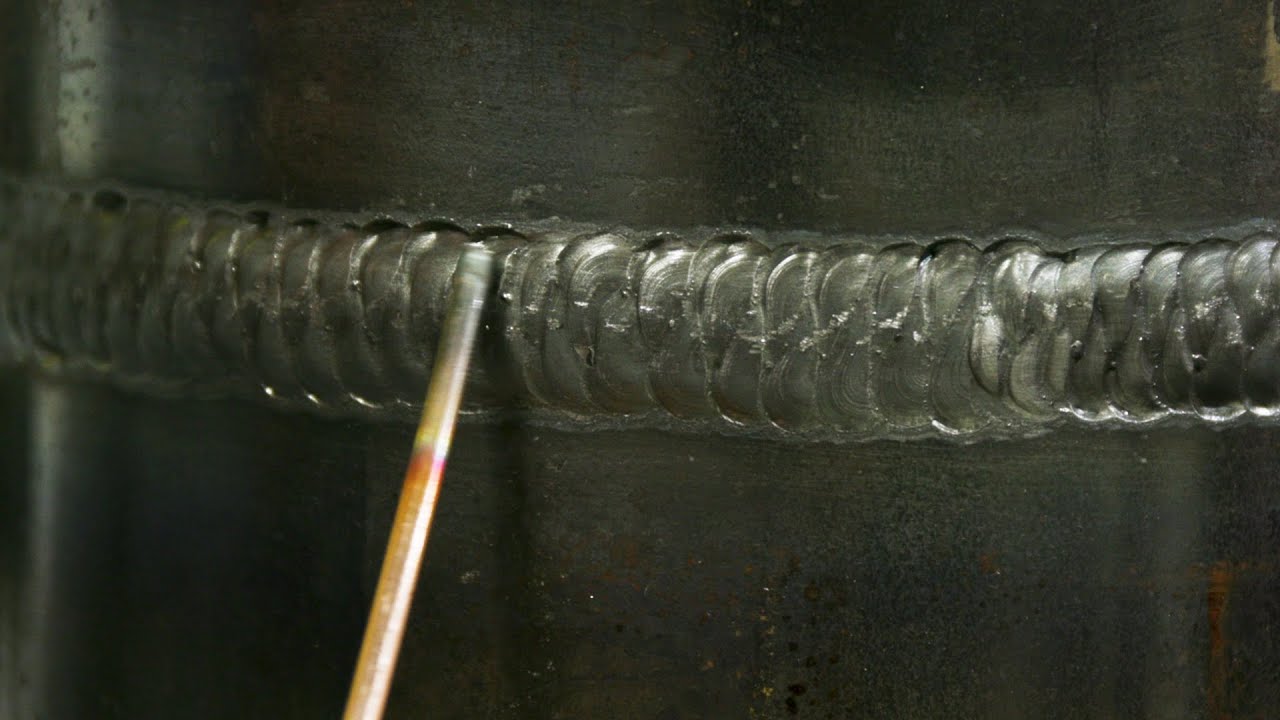

To reduce the danger of undercutting in welding, welders can utilize strategic welding methods focused on boosting the top quality and stability of the weld joints. One reliable method is to adjust the welding criteria, such as voltage, existing, and travel speed, to guarantee appropriate warmth input and deposition. Maintaining an ideal electrode angle and ensuring constant travel rate can likewise assist protect against undercut. In addition, making use of the correct welding technique for the particular joint setup, such as weave or stringer beads, can add to minimizing damaging. Preventing weld undercut.

In addition, appropriate joint preparation, including making certain tidy base materials devoid of contaminants and making use of the proper welding consumables, is important in avoiding undercut defects. Using back-step welding methods and controlling the weld grain profile can also aid distribute heat equally and reduce the risk of undercut. Normal evaluation of the weld joint throughout and after welding, in addition to implementing quality control steps, can aid in identifying and resolving damaging problems quickly. By implementing these techniques vigilantly, welders can attain flawless fabrication results with very little undercut problems.

Importance of Proper Welding Specifications

Choosing and keeping appropriate welding specifications is essential for attaining successful welds with minimal issues. Welding parameters describe variables such as voltage, current, take a trip rate, electrode angle, and protecting gas flow price that straight influence the welding procedure. These criteria have to be meticulously adjusted based upon the sort of material being welded, its thickness, and the welding strategy utilized.

Appropriate welding criteria make certain the correct amount of heat is related to melt the base metals and filler material uniformly. If the parameters are established expensive, it can cause extreme warm input, triggering distortion, spatter, or burn-through. On the other hand, if the parameters are also reduced, insufficient combination, lack of penetration, or damaging might happen.

High Quality Assurance in Welding Operations

Conclusion

Finally, grasping the art of welding requires a comprehensive understanding of undercut welding, its causes, and strategies to avoid it. By guaranteeing correct welding specifications and executing quality control practices, remarkable construction results can be attained. It is vital for welders to consistently make every effort for excellence in their welding procedures to prevent undercut concerns and create high-quality welds.

Undercut welding, a typical problem in welding procedures, occurs when the weld steel doesn't appropriately fill the groove and leaves a groove or clinical depression along the welded joint.To stop undercut welding, welders should make sure proper welding specifications, such as readjusting the present, voltage, traveling rate, and preserving the proper electrode angle. Inadequate welding inaccurate or existing welding rate can likewise add to undercut.To mitigate the risk of undercutting in welding, welders can employ tactical welding techniques intended at improving the top quality and integrity of the weld joints.In conclusion, mastering this article the art of welding needs a complete understanding of undercut welding, its causes, and methods to stop it.

Report this page